RELOADING 101

The Basics of Reloading

Before you become a reloading expert you need to master the basics.

Reloading Basics

By Johnny Peruch

This article will discuss the very basics of reloading. Equipment will be the biggest investment a beginner will make when they decide to start reloading. The second biggest investment will be time. This money saving activity takes time and a little bit of effort. First thing is first, what equipment is needed to start?

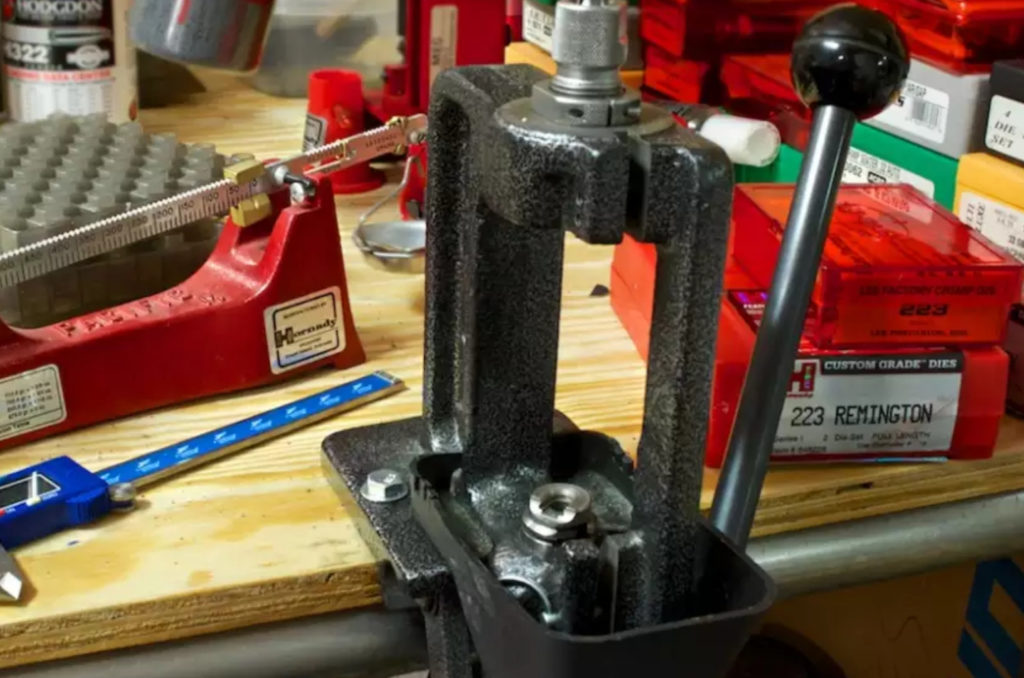

The equipment needed to start reloading consist of a reloading press, dies, case prepping tools, primers, scales, powder, and bullets. A reloading press will be the single most expensive piece of equipment you will need to get started. When deciding on a press, there are many options such as which manufacturer to buy from and also what style of press to buy. The major players in the reloading industry are Hornady, Lee Precision, RCBS, Lyman, and Dillon. All of these companies all offer quality products, pricing on some are more reasonable than others but all are quality and dependable. All of these companies offer different styles of presses from single stage, turret, and progressive presses. Single stage presses require the least amount of investment and offer only one die station. They require each stage of reloading to be done separately. For example, all cases must be sized, primed, expanded seated, and crimped separately.

Turret presses allow for multiple dies to be used. These styles of presses have a wheel (turret) with between 3-5 die station depending on make and model. This allows for a case to be sized, turned the next station, expanded, turned to the next station, seated, turned to next station, and crimped. An advantage to these presses is that the reloader does not have to readjust dies. They can set-up a turret for a certain caliber and another turret (sold separately) set-up for a different caliber and simply change turrets. This makes for easy and simple caliber transitions. Progressive presses allow for the most efficiency but are generally require the most amount of investment.

Progressive allow for a case to be sized, seated, and crimped all at once. These presses also have between 3-5 die stations depending on make and model. When the lever of this style of press is pulled down, one case is fed onto the shell plate, once case is sized, one is expanded and charged with powder, one is seated, and one is crimped. All this with one pull of the lever. These presses usually take longer to set-up than any other style of press but once the reloader has it set-up, it will generate quality and consistent reloads for years to come.

Die sets are the next piece of equipment needed to reload. Dies are available in virtually any caliber. One thing to keep in mind is the rarer the caliber, the more expensive the die set. For a common caliber, dies can be as reasonable as 30-60 bucks. For rare calibers, dies can cost well over 100 bucks. All of this aside, if dies are taken care of, they can last a life time.

Case prepping tools are not to be forgotten. These tools include case trimmers, primer pocket tools, and tumblers. Case trimmers are necessary for safe and accurate reloading. This tool is used to keep the length of the case w/o the bullet to proper specs. It is important to trim your cases AFTER they have been sized. Chamfering and deburring are necessary to get rid of sharp edges after case trimming. Primer pocket tools are used for primer seating and powder ignition. These tool include a flash hole-uniformer, pocket-uniformer, pocket-reamer, and pocket-cleaner.

Next is primers and powder. Primers come in large rifle, small rifle, large pistol, and small pistol. Consult a reloading manual to make absolutely sure which primer your caliber requires. Primers are sold by the hundred and the thousand. Buying in bulk can save the reloader even more money. Deciding which powder to use can be a hard decision. One way to decide is by using the same powder for different calibers. Consult a reloading manual to determine if your powder choice is compatible for the list of calibers you want to reload. Keep in mind that a pound of powder is 7,000 grains. This will come in handy when trying to figure the cost of a reload. Powders usually run between 25-30 dollars a pound. A powder scale is used to weigh out each charge to ensure proper and safe loading of a case. Investing in a quality digital scale will save the reloader precious time.

There are many choices for bullets available on the market. Some categories of bullets are match grade, non-match grade and lead. Match grade bullets are going to be the most expensive bullet type but offer improved accuracy compared to non-match grade bullets. Non-match grade bullets are perfect for plinking and cost less. Lead bullets will the most reasonable option but come with some draw backs. More frequent weapon cleaning and possible risk of leading (lead build up in bore and rifling).